Corknut

María Eugenia González de Quevedo

WHAT IS CORKNUT

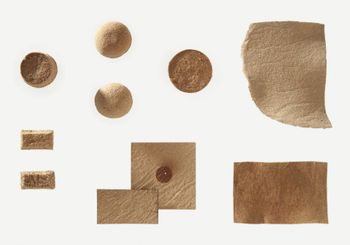

This cork-like biomaterial is made of peanut shells, water, pectin, and glycerine. It works as an alternative to plastic, leather, or cardboard while repurposing organic waste. It can be extruded, cast into a mold, or dried as a flat ductile surface, as well as cut (by machine, scissors, laser), engraved, and sewn.

When experimenting with my organic food waste, I realized that the external shell or hull that surrounds the nut is often 30% of the peanut, which generates large amounts of waste. In peanut-producing countries, it is usually burned, dumped, or left to deteriorate naturally. The food industry makes this material easily available, and its potential should be further explored.

Cork is a biodegradable alternative to plastic. However, the cork Oak tree grows mainly in the Mediterranean. Also, laws dictate that a tree must grow for 25-34 years before the first harvest, and the cork is harvested by hand once every 9 years.

However, the growing cycle of a peanut takes 4 to 5 months and its plant improves soil and benefits other crops. This healthy nut is highly consumed worldwide, it has more protein than any other, as well as the smallest carbon footprint and use of water (one-tenth of the needed to grow other nuts).

Just as plastic, Corknut is made of organic polymers (cellulose, lignin, and hemicellulose, structural components of the plant cell wall). Its high porosity provides the material with lightness and insulation capabilities: it absorbs water, sound, and heat. It could replace expanded polystyrene.

The lignin component acts as an adhesive insoluble in water and provides rigidity, which would make Corknut a light and resistant building or packaging material. When dried as a thin layer, has similar properties to leather.

HOW TO MAKE IT

Ingredients:

93 gr water

8 gr pectin

10 gr glycerine

11 gr peanut shell

Tools:

Blender or coffee grinder

Sieve (optional)

Scale

Pot

Stove

Spoon (to stir)

Mould (silicone, paper cup), oven paper, non-stick material

Process:

1) blend peeled peanut shells until they become a thin powder (sieve to obtain a thinner result)

2) dissolve the pectin in the water, then add the rest of the ingredients (glycerine and peanut shell powder)

3) heat the mixture on low power in a pot while steady stirring, until the mixture, becomes smoother, less thick

4) cast mixture into a silicone/coated paper mold or apply to a surface

5) let it dry or bake in the oven at low temperature for quicker drying

Difficulty: 1

Duration: 30 minutes for preparing and up to 3 days to have a dry product

Starting from the top, in the left and center part of the image, pumpkin peels and seeds bioplastic are displayed. At the right, there is a zucchini-based one. In the center, two pieces of hemp bioplastic are shown. At the bottom right corner, there are two samples of acorn “cork”. As we move towards the left, there are the results from different recipes with onion and garlic peels. To follow, there is an example of eggshell “clay”. And lastly, a chestnut “leather”.

Do-It-Yourself Materials

Many thanks to our guest speakers and supporters: Werner Schönthaler, Daria Habicher, Andrea Sebastianelli, Ghali Egger, Hannes Götsch, Yuri Borgianni, Valentina Rognoli, Barbara Pollini, Sofia Duarte and Luca Alessandrini.

Press release: GÄSTE OSPITI GUESTS